We reduce production costs and eliminate chaos — without risks or process interruptions

Experience in the US, Europe, and the CIS. We speak the language of business owners. We get things done — together

Why now?

Rising raw material and logistics costs

Margin pressure

Talent shortage

Mistakes are getting more expensive

Your competitors are already optimizing

We don’t do reports for the sake of it.

We step into your business with you —

reducing losses, increasing control, and growing profits

Our clients are owners and managers of small and medium-sized businesses

We work with manufacturers of any scale and specialization — from small workshops to full-cycle production.

Small and medium-sized manufacturing

Casting, machining, packaging, food processing, assembly

Businesses where “everything depends on people”

Those who tried to “implement Lean” — and got burned

What our work gives you

Analysis of the current model and loss map

We diagnose processes, identify bottlenecks, and provide a clear picture

Streamlined processes instead of manual management

The production cycle becomes manageable and predictable

Clear and visual management system

Visualization of “how it should be,” control of key points and bottlenecks

Reduction of production costs without loss of quality

Through optimization of materials, logistics, and labor

Your team is ready to take responsibility and show initiative

People understand their tasks and work for results

The owner frees up their head and hands

Less firefighting, more time for strategy

We don’t just give recommendations — we do it together

Goal: eliminate waste, simplify processes, and make every step intentional and necessary.

- Together with your team, we identify and eliminate the 7 types of waste

- We optimize flows: materials, information, tasks

- We visualize the process — everyone understands what they do and why

- We implement standards and checklists — without overloading the staff

- We reduce setup times, downtime, and hidden losses

Goal: build in control and preventive measures at every stage — instead of catching defects at the end.

- Critical control points and preventive actions

- Control is built into the process — without duplication or formalism

- Preparation for certifications, audits, ISO/TS

- Quality culture: not “punish,” but “prevent”

Goal: increase margin and competitiveness — without sacrifices or chaos.

- Diagnostics of all areas: procurement, logistics, warehouse, personnel

- Cost structure rebuilt — at the process level

- Elimination of unnecessary links, reduction of inventory

- Automation — if needed

Goal: eliminate dependence on “indispensable people” and make processes transparent.

- Simple and clear standards

- Everything is visible: tasks, statuses, results

- Clear roles, areas of responsibility, and understandable metrics

- Standards that work — not ones that collect dust

Goal: change the system without paralyzing production.

- Everything is done step by step: fast implementation → adjustment → scaling

- No “revolutions” or shop floor shutdowns

- Quick initial results to engage the team

Goal: not reports — transformation.

- We step into the shop floor, warehouse, office, spreadsheets — with our hands and minds

- We don’t just give recommendations — we do it together

- We train and engage employees in the changes

- We remove barriers between “office” and “production”

Work Formats

Diagnostics

Audit

Support

Audit + Support

Turnkey transformation

Online Products (ERP, CRM)

Training Programs

Why choose us?

01

Deep industry insight and practical manufacturing experience.

02

We collaborate with your team both in the office and on the production floor.

03

We implement real solutions together with your team, creating lasting change.

04

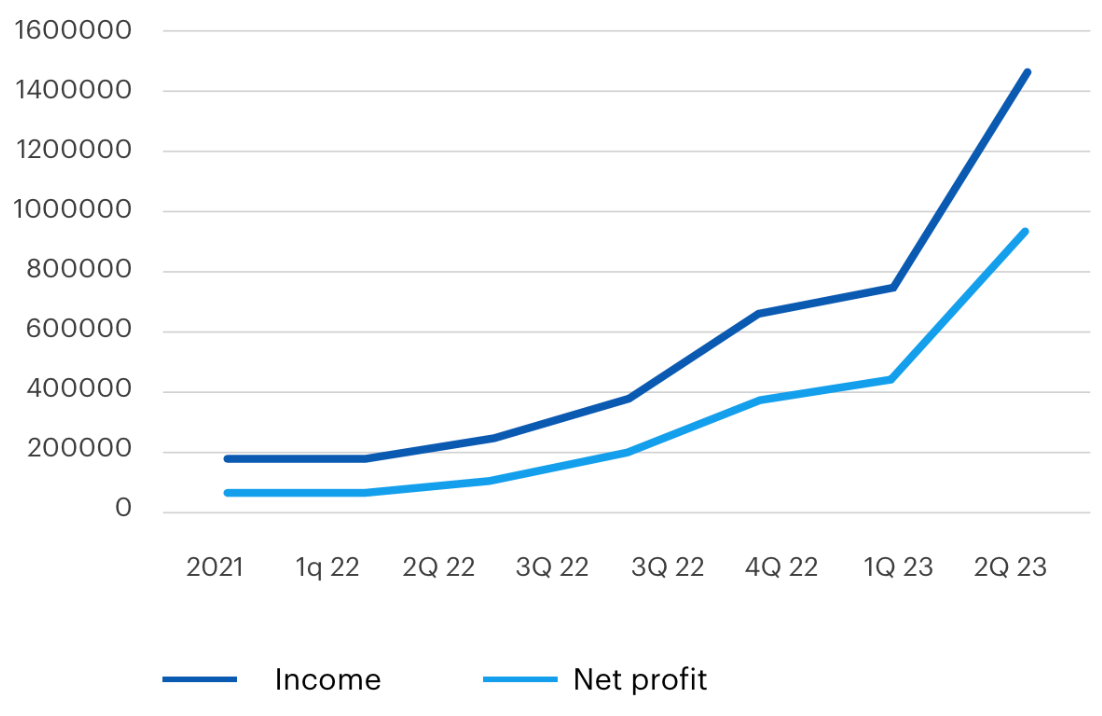

You achieve noticeable results within just 3 months in the form of increased revenue, margin, and profit.

Who are we?

The company was born at the intersection of manufacturing practice and management consulting — that’s our strength: we know how to analyze and implement. Our project geography spans from the US to the CIS, but the core goal is always the same — tangible, measurable results.

We work with manufacturing businesses where it truly matters: on the shop floor, at the production line, and inside the owner’s mindset. Our methods are based on an engineering approach and common sense, and a deep understanding of business realities.

An international consulting company with projects in the US, Europe, and the CIS

We understand how business owners think

Over 12 years of experience

From owner to owner

We don’t place ourselves above your team.

We become part of it.

First together. Later — without us, but with a working system.

Leave a request

Fill out the form — and we’ll offer a solution tailored to you.